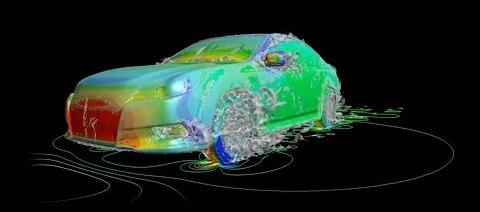

Automotive aerodynamics simulation using a supercomputer

The fluid simulations currently done by automakers use up to a hundred million cells around the vehicle. By contrast, simulations on the K computer use up to 20 billion cells. Compared with conventional simulations, this achieves tens of times higher resolution. Also, creating the computational model, or lattice, used in large-scale simulations had been a big issue. But in ultra-large-scale analysis using the K computer, careful attention to how the lattice is defined makes simulation at least 100 times faster. Through such new methods of analysis, using the K computer has reduced the margin of error in air resistance prediction from about 5% to 2%. Such high-precision air resistance prediction will be a great help in developing cars with even higher fuel efficiency.

"Wind tunnel tests only measure the effects of a constant wind speed on a stationary vehicle, but when an actual vehicle is running outside, it encounters sudden gusts, and it’s being driven by a person. The force on the vehicle at such times couldn’t be understood in a wind tunnel. Using the K computer, we’ve become able to understand it. The K computer makes it possible to do new tests that can’t be done in wind tunnels; in other words, computer tests."

Some of this research on aerodynamics simulation is being done by a consortium, including 13 Japanese automakers and related companies, and four research institutes. From now on, the research will take account of needs in Japanese industries, with the aim of transferring technology to the automotive industry.

"Simulations may concern collisions, the engine, and many other aspects. Various simulations are done in the process of design when making an automobile. We’d like to integrate them all, by providing a single simulation system. Then, as the next step, our future vision is: Being able to make really good cars when such a system becomes available. Automotive design and development is basically done on a sectional basis, with aerodynamics and collision behavior considered separately, but the single term “simulation” can unify all those processes. We think that kind of possibility does exist."